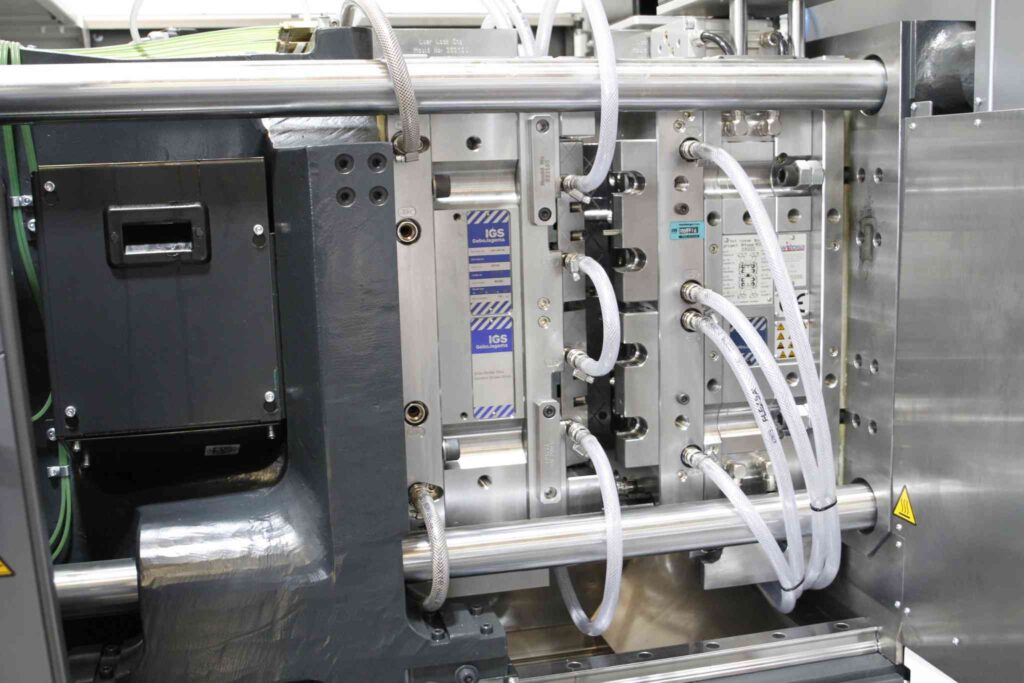

We are proud to announce an important development at Sterisets. We have put a state-of-the-art, 16-cavity mold into production, specifically designed for injection molding high-quality Luer Lock caps. This investment, with the mold perfectly aligned to our new injection molding machine, represents a significant step forward in both the quality and speed of our operations.

This precision mold, manufactured by a renowned specialist in high-precision molds, enables us to produce at higher capacity. This allows us to deliver in larger volumes and meet the growing demand from our customers.

Moreover, the advanced technology of the mold guarantees consistently superior cap quality and a smooth unscrewing experience, enhancing usability for healthcare professionals. This was our main driver in choosing this specific mold. The Luer Lock cap is a critical component that ensures the integrity of syringes and prevents leakage.

At Sterisets, we are aware of our responsibility within the healthcare chain. This investment underscores our commitment to providing products that are not only produced efficiently, but above all, contribute to the safety and well-being of patients.